PARTS & SERVICE

Curb Roller CM4000 & CM4100

• What is this aluminum block on the hydraulic hoses and is the machine variable speed?

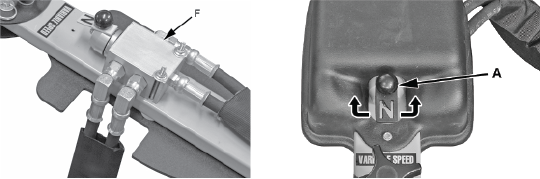

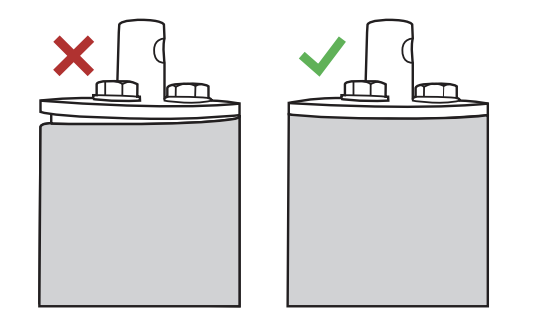

The Curb Roller ships with an in-line flow control block. This block allows our equipment to function properly with nearly all hydraulic power sources. This block regulates hydraulic oil flow and PSI to the machine protecting it from overload or shock from sudden directional change or stop. (Tampering with or removing this block voids warranty.)

• How do I adjust the direction or speed of the Curb Roller?

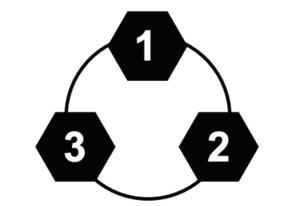

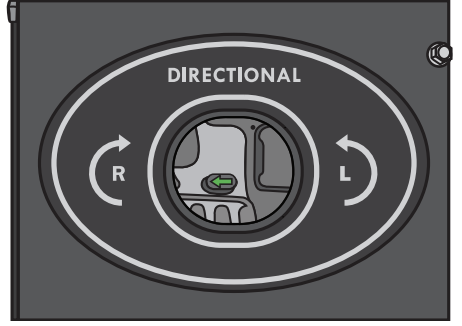

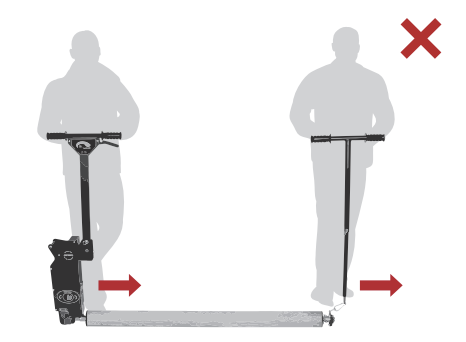

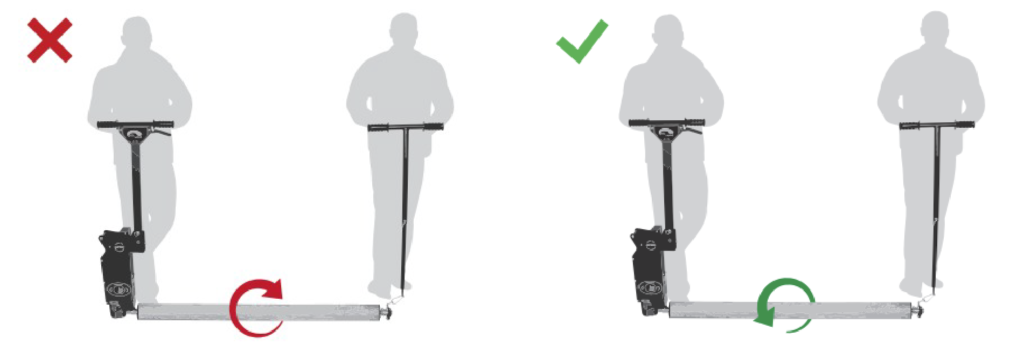

The Curb Roller is designed to easily adapt to an either direction pull. It also comes with a flow control block that is factory set and NOT ADJUSTABLE. To adapt the direction of pull, flip the machine over, change the directional valve (F) position, move the drum sweep to the top side of the drum, and done! For finer speed and direction adjustment, on the handle of the Curb Roller is a variable speed directional valve which operates left to right depending on the direction of the desired rotation. The Curb Roller also comes with a safety tab which is located on the directional knob (A) and can be manually set to allow the valve to open towards the right or open towards the left. To set the safety tab, loosen the knob on the directional valve, turning it counterclockwise. Once the safety stop is in the desired position, re-tighten the knob.

• What slump should I use with the Curb Roller?

The slump varies from job to job depending on the mix design used. We recommend using a 3 to 3-1/2 inch slump.

• How heavy is the Curb Roller?

The Curb Roller weighs approximately 200 lbs with a standard drum attached. Some custom drums and machines will weigh more. Two individuals can easily lift the machine.

• What is the drum or screed made of?

The drum is fabricated using metal spinnings welded to various sizes of heavy wall pipe. Some custom profiles with slopes and odd shapes are rolled out of a lighter metal to achieve desired profile.

• What is the power source for the Curb Roller?

The Curb Roller is powered hydraulically and will run off nearly any hydraulic power source (i.e skid-steer, mini-excavator, tractor, hydraulic power pack, etc). However, if you’d like a hydraulic power unit specifically designed for use with the Curb Roller, we manufacture one called the Hydra-Pack.

• How many feet of hydraulic hose comes with the machine and can I add more if I want?

The Curb Roller CM4000 comes standard with 25′ foot of hose. Additional hose extensions can be purchased, but we recommend not exceeding 100′ of hose per machine.

• What if I need several drums or a job specific profile?

The Curb Roller has the ability to easily change drums, which makes it ideal for any curb and gutter job. We currently have over 30 stock drums available (which can be viewed here), and we can also make custom profiles perfect for almost any job. (You can take a look at some past custom drums and submit a form for a quote here.)

• What kind of forming is required for effective and efficient use?

The Curb Roller will work on wood, metal, plastic, and masonite forming as well as run off existing concrete. Keeping your form stakes and bracing below the top of the form will allow for smooth operation.

• Is the Curb Roller hard to operate?

The Curb Roller, like any other machine, takes a very basic understanding of hydraulics and concrete. Because of its simple design, most operators become proficient with it on the first or second use. The Curb Roller comes with a waist belt designed so the operator can use proper positioning and body weight transfer to pull the machine.

• Does Curb Roller Mfg warranty their equipment?

We proudly offer a 3 year warranty on the Curb Roller CM4000.

• We are located outside of the United States and Canada. Can we still buy your machines?

Of course! We have many happy customers outside of the United States and Canada. We just ask that you contact our international dealer J.D. Honigberg to set up your order. More information can be found here.

Hydra-Screed HS3000

• What is this aluminum block on the hydraulic hoses and is the machine variable speed?

The Hydra-Screed ships with this in-line flow control block. This block allows our equipment to function properly with nearly all hydraulic power sources. This block regulates hydraulic oil flow and PSI to the machine protecting it from overload or shock from sudden directional change or stop. (Tampering with or removing this block voids warranty.)

• How do I adjust the direction or speed of the Hydra-Screed?

The Hydra-Screed comes standard with a flow control block. This is factory set and NOT adjustable. On the handle of the Hydra-Screed is a variable speed directional valve (F) which operates left to right depending on the direction of desired rotation. The Hydra-Screed has a safety tab which is located on the directional knob (A) and can be manually set to allow the valve to open towards the right or open to the left. To set the safety tab loosen the knob on the directional valve, turning it counter-clockwise. Once the safety stop is in the desired position, re-tighten the knob.

• How heavy is the Hydra-Screed?

The Hydra-Screed weighs approximately 100 lbs before the desired pipe length is added.

• What is the power source for the Hydra-Screed?

Any hydraulic source that maintains 4 gallons per minute can effectively run the Hydra-Screed (i.e skid-steer, mini-excavator, tractor, hydraulic power pack, etc). However, if you’d like a hydraulic power unit specifically designed for use with the Hydra-Screed, we manufacture one called the Hydra-Pack.

• How many feet of hydraulic hose comes with the machine and can I add more if I want?

The Hydra-Screed comes with 40′ of hose. Additional hose extensions can be purchased, but we recommend not exceeding 100′ of hose per machine.

• What if I need several pipes or a job specific profile?

The Hydra-Screed has the ability to easily change pipes or custom profiles. The roller pipe is made of 6 inch 10 gauge round spouting and can be purchased in the desired lengths from us or your local steel provider. If you are interested in a custom profile such as a crowned street, v-gutter, flume or other shape, please send us an email with your desired specifications at info@curbroller.com or call us at 785-467-3132.

• What kind of forming is required for effective and efficient use?

The Hydra-Screed will work on wood, metal, plastic, and masonite forming as well as run off existing concrete. Keeping your form stakes and bracing below the top of the form will allow for smoother operation.

• Does Curb Roller Mfg warranty their equipment?

We proudly offer a 3 year warranty on the Hydra-Screed HS3000.

• We are located outside of the United States and Canada. Can we still buy your machines?

Of course! We have many happy customers outside of the United States and Canada. We just ask that you contact our international dealer J.D. Honigberg to set up your order. More information can be found here.

Batt Screed BS6000

• How do I install the expandable pipe inserts?

To install the expandable pipe inserts into the pipe you will need a ¾” ratcheting socket, wrench, or preferrably a battery impact. Push expandable insert into the end of the pipe until flange is tight against pipe end. Equally tighten the lug bolts on the expandable pipe inserts to ensure proper fitting into pipe.

• How do I attach the drive and static ends to the pipe?

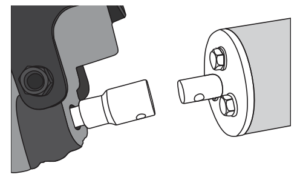

Once both expandable screed ends are properly and securely installed in the pipe, the next step is to attach the drive end to the pipe. Make sure the battery is removed from the machine to protect the operator in case of accidental trigger activation. Lay the drive unit down next to the pipe and align the chuck to the expandable insert shaft.

Push drive head all the way onto the shaft. Take one hand and roll the pipe forward until you can see down through the chuck and shaft hole. Once you have the two holes aligned install the lock pin. The drive end is now installed. Repeat this process with the T-bar assembly on the idle end.

• Why is my trigger lever sticking?

• Why does the battery life seem short?

• Why is my machine shaking so much?

Make sure the pipe ends have been cut true and are not angled. Ends not properly cut will cause excessive shaking and may cause damage to the drive unit. Use a factory cut end of the pipe whenever possible to install the drive end on.

Other things to do include checking to see if the pipe itself is bent, and avoid abrupt or excessive movement of the drive unit to reposition pipe location.

• Why won’t the battery access door stay shut?

If the door isn’t staying shut, check and if need be tighten door bolt.

• Why is nothing happening when I pull the speed lever?

• How heavy is the Batt Screed?

The Batt Screed weighs about 75 lbs without an aluminum pipe attached.

• What pipe should be used with the Batt Screed?

4″ SCH40 aluminum pipe or our patent-pending Lynx Screed System. If buying from an outside source, we recommend using this aluminum pipe: 6061-T6 EXTRUDED PORTHOLE PIPE – ASTM B429 – 4” SCH 40 (4.500 OD X .237 W)

• What is the power source for the Batt Screed?

Get power anywhere with the removable and rechargeable DeWalt FLEXVOLT 60-volt lithium-ion battery, perfect for impressive power and run time.

• Can the Batt Screed be pulled in only one direction?

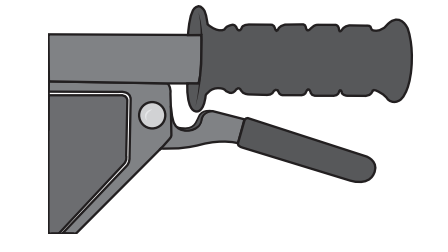

The Batt Screed is designed to easily adapt to an either direction pull. Just push the directional button all the way on the desired side so the pipe spins away from the operator.

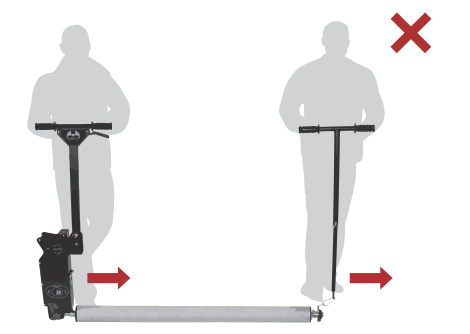

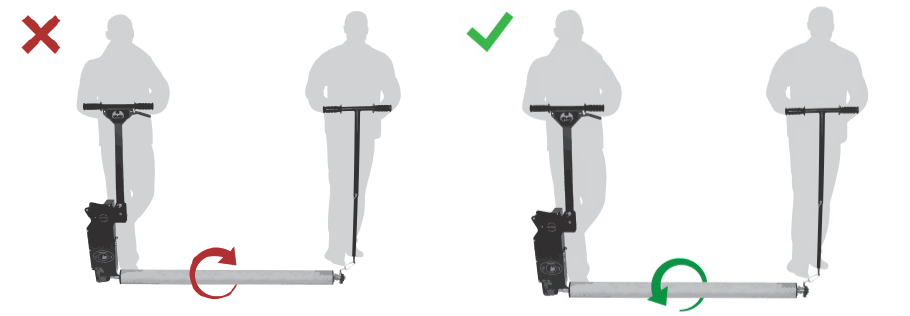

• Which way should the pipe spin?

With both operators holding firmly on the handles lightly pull the variable speed trigger to see which direction the pipe turns. The pipe should roll away from the operators for proper operation. If the pipe rolls towards the operators, simply change the rotation of the pipe by pushing the directional button on the side of the machine.

• Does the machine only run at one speed?

No. Thanks to the adjustable right or left hand speed control, how much grip you put on the lever will change how fast or slow the pipe spins.

• Does Curb Roller Mfg warranty their equipment?

We do! Depending on the machine there are different warranty lengths. Currently we offer a 1 year warranty on the Batt Screed BS6000 to the original purchaser.

• We are located outside of the United States and Canada. Can we still buy your machines?

Of course! We have many happy customers outside of the United States and Canada. We just ask that you contact our international dealer J.D. Honigberg to set up your order. More information can be found here.

Eel Screed ES6100

• How do I install the expandable pipe inserts?

To install the expandable pipe inserts into the pipe you will need a ¾” ratcheting socket, wrench, or preferrably a battery impact. Push expandable insert into the end of the pipe until flange is tight against pipe end. Equally tighten the lug bolts on the expandable pipe inserts to ensure proper fitting into pipe.

• How do I attach the drive and static ends to the pipe?

Once both expandable screed ends are properly and securely installed in the pipe, the next step is to attach the drive end to the pipe. Make sure the screed is unplugged to protect the operator in case of accidental trigger activation. Lay the drive unit down next to the pipe and align the chuck to the expandable insert shaft.

Push drive head all the way onto the shaft. Take one hand and roll the pipe forward until you can see down through the chuck and shaft hole. Once you have the two holes aligned install the lock pin. The drive end is now installed. Repeat this process with the T-bar assembly on the idle end.

• Why is my trigger lever sticking?

• Why is my machine shaking so much?

Make sure the pipe ends have been cut true and are not angled. Ends not properly cut will cause excessive shaking and may cause damage to the drive unit. Use a factory cut end of the pipe whenever possible to install the drive end on.

Other things to do include checking to see if the pipe itself is bent, and avoid abrupt or excessive movement of the drive unit to reposition pipe location.

• Why is nothing happening when I pull the speed lever?

• How heavy is the Eel Screed?

The Eel Screed weighs about 70 lbs without an aluminum pipe attached.

• What pipe should be used with the Eel Screed?

4″ SCH40 aluminum pipe or our patent-pending Lynx Screed System. If buying from an outside source, we recommend using this aluminum pipe: 6061-T6 EXTRUDED PORTHOLE PIPE – ASTM B429 – 4” SCH 40 (4.500 OD X .237 W)

• What is the power source for the Eel Screed?

The Eel Screed is powered by plugging the cord into a 120V, 60hz outlet or generator

• Can the Eel Screed be pulled in only one direction?

The Eel Screed is designed to easily adapt to an either direction pull. Just push the directional button all the way on the desired side so the pipe spins away from the operator.

• Which way should the pipe spin?

With both operators holding firmly on the handles lightly pull the variable speed trigger to see which direction the pipe turns. The pipe should roll away from the operators for proper operation. If the pipe rolls towards the operators, simply change the rotation of the pipe by pushing the directional button on the side of the machine.

• Does the machine only run at one speed?

No. Thanks to the adjustable right or left hand speed control, how much grip you put on the lever will change how fast or slow the pipe spins.

• Does Curb Roller Mfg warranty their equipment?

We do! Depending on the machine there are different warranty lengths. Currently we offer a 1 year warranty on the Eel Screed ES6000 to the original purchaser.

• We are located outside of the United States and Canada. Can we still buy your machines?

Of course! We have many happy customers outside of the United States and Canada. We just ask that you contact our international dealer J.D. Honigberg to set up your order. More information can be found here.

Hydra-Pack HP1300

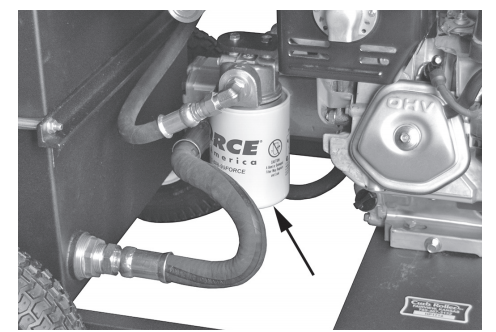

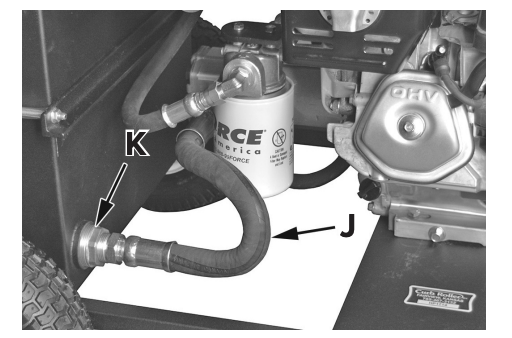

• How often should I change the hydraulic oil filter?

• How often should I change the hydraulic oil?

• Where should the Hydra-Pack be used?

Due to the ease of portability, the HP1300 is perfect for those job sites where your skid loader or mini excavator won’t fit. An 11-gallon tank provides plenty of hydraulic fluid and cooling capacity, and the 13” pneumatic tires let you navigate through the rough terrain of any job site.

• What can the Hydra-Pack be used for?

A powerful 13 horse Honda GX390 gas engine easily runs our Curb Roller CM4000 and Hydra-Screed HS3000 systems, as well as hydraulic saws, jack hammers, and other hydraulic tools. At the size of a standard generator, the Hydra-Pack HP1300 easily fits in the back of your pickup or job trailer.

• How heavy is the Hydra-Pack?

The Hydra-Pack weighs about 300 lbs before gas is added to the engine fuel tank.

• What is the hydraulic reservoir capacity?

The hydraulic reservoir capacity is 11 gallons (41.6 l).

• What is the hydraulic flow?

The hydraulic flow is 7 gpm (26.5 lpm) dependent on engine RPM.

• What is the maximun hydraulic pressure?

The maximum hydraulic pressure for the Hydra-Pack is 2300 psi (158.6 bar).

• Does Curb Roller Mfg warranty their equipment?

We proudly offer a 3 year warranty on the Hydra-Pack HP1300.

• We are located outside of the United States and Canada. Can we still buy your machines?

Of course! We have many happy customers outside of the United States and Canada. We just ask that you contact our international dealer J.D. Honigberg to set up your order. More information can be found here.

Badger Curb Maker CM4600

• Curb Maker Drum Does Not Spin

-

- Check the battery by pressing the indicator button

- Check the pin that connects the drum shaft to the drive chuck

- Check trigger and linkage for bent parts or concrete build up.

- Remove battery and reinsert.

- Check directional button and make sure it is pressed all the way in.

• Curb Maker Is Hard To Pull

-

-

- The Curb Maker comes with an operator’s belt.

- The belt reduces the difficulty of pulling the machine.

- Concrete may be too dry or a difficult mix to screed. See the ideal mix information.

-

• Curb Maker Will Not Stay On Forms

-

- Verify that all stakes and pins are below the top of the form.

- Check the amount of concrete in front of the machine.

- Make sure there is no more than two inches of excess.

• Access Door Won’t Stay Closed

-

-

- Tighten door bolt.

-

• What are the drums made out of?

Curb Maker drums are made out of steel. The average life of a drum is 40 to 60,000 linear feet.

• Can I pour just one curb shape with the Curb Maker?

The Curb Maker can be purchased with any of our stocked drum styles or a custom fabrication for specific jobs.

• What drives the Curb Maker?

The Curb Maker runs off of one DeWalt FLEXVOLT battery. One battery should power the Curb Maker to pour 150-200 linear feet of curb.

• Can I use the Curb Maker for catch or spill curb?

A standard curb drum can be used to pour catch or spill curb with the heights being adjusted by the operator.

• How do I change the direction of the Curb Maker?

The direction of the drum is changed with the directional button on the drill. When switching directions, you must also swap the drum sweep to the other side. The drum sweep should always be on the top side of the drum.

• How do I adjust the speed of the Curb Maker?

The speed is adjusted the same as most cordless power tools- by how much you squeeze the trigger. If the trigger is squeezed to the fullest extent, the drum will go full speed. If the trigger is barely squeezed, the drum will move slowly.

• Can I change the drum profile on a Curb Maker?

The Curb Maker is designed to easily adapt between different curb profiles by changing the drums attached to the main frame.

• Can the Curb Maker power curb and gutter drums?

No. The Curb Maker is designed for curb only drums.

• Does Curb Roller Mfg warranty their equipment?

We do! Depending on the machine there are different warranty lengths. Currently we offer a 1 year warranty on the Badger Curb Maker CM46000 to the original purchaser.

• We are located outside of the United States and Canada. Can we still buy your machines?

Of course! We have many happy customers outside of the United States and Canada. We just ask that you contact our international dealer J.D. Honigberg to set up your order. More information can be found here.